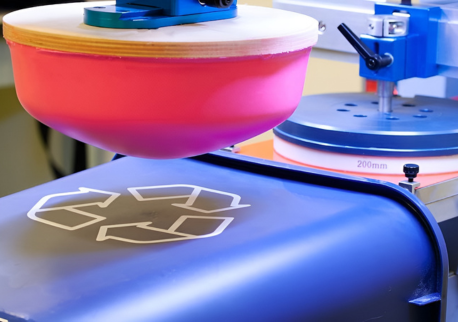

Pad printing is a specialized printing technique that allows transferring ink onto surfaces that are flat, curved, textured, or irregular. This makes it ideal for industries that require precise and permanent marking on small or complex components.

In 2026, pad printing machines are witnessing strong adoption across India and globally due to their versatility, cost-effectiveness, and efficiency. Manufacturers prefer pad printing over other methods because it can print on surfaces that are challenging for traditional techniques like screen printing or digital printing.

Applications include electronics, automotive, medical devices, consumer products, and promotional items, making pad printing an essential component in modern manufacturing and branding strategies.

1. Key Factors Driving Market Growth in 2026

1.1 Increasing Use in Electronics & Electrical Components

The electronics sector is a major driver of pad printing machine demand. Components like switches, panels, chargers, connectors, and buttons require precise, permanent markings that are resistant to wear.

Pad printing machines offer:

- High accuracy on small and irregular surfaces

- Durable marks that withstand handling and environmental conditions

- Efficient production for large volumes of components

With the rise of electric vehicles (EVs) and advanced electronics, the need for high-quality, fast, and reliable printing is expected to grow steadily.

1.2 Demand from Automotive & Industrial Applications

Automotive manufacturing is another major market for pad printing machines. Interior and exterior components such as:

- Dashboard panels

- Control knobs

- Gear indicators

- Switches and buttons

Pad printing machines are preferred due to their ability to handle complex shapes while ensuring consistency.

As EV production increases and automotive components become more sophisticated, pad printing will continue to play a critical role in the industry.

1.3 Growth in FMCG and Cosmetic Packaging

The FMCG and cosmetics sectors increasingly use pad printing to enhance packaging aesthetics. Examples include:

- Bottles, caps, and jars

- Cosmetic applicators and containers

- Packaging inserts and promotional packaging

Pad printing allows multi-colour printing and intricate designs, helping brands differentiate their products in highly competitive markets. With consumer focus on premium packaging, these sectors are contributing to the growing demand for pad printing machines in 2026.

1.4 Rise in Promotional Merchandise and Custom Gifts

Corporate gifting, personalized merchandise, and promotional products are experiencing growth. Pad printing machines are widely used for printing on:

- Pens

- Keychains

- Mugs

- USB devices

- Corporate gifts

This segment benefits from low-cost, versatile, and high-quality printing, enabling businesses to deliver customized branding efficiently.

2. Technological Advancements in Pad Printing Machines

2.1 Automation and Digitally Controlled Systems

Modern pad printing machines in 2026 increasingly feature semi-automatic and fully automatic systems. Benefits include:

- Higher production speed

- Consistent print quality

- Reduced labor requirements

- Programmable operations for multiple jobs

Automation is helping manufacturers scale production and reduce errors.

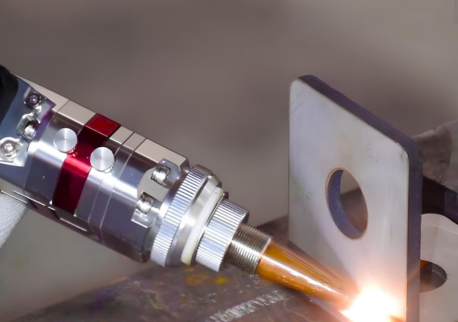

2.2 Laser-Etched Printing Plates

Laser-etched cliché plates improve print accuracy and durability. Advantages include:

- Longer plate lifeM

- Higher precision for complex designsM

- Reduced maintenance costsM

- Consistent print results across large production runsM

This advancement enhances efficiency and reduces operational downtime.

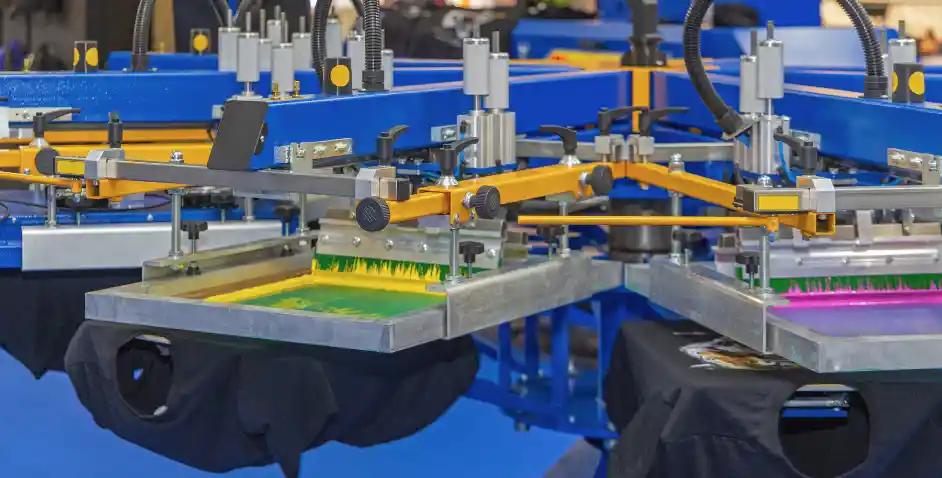

2.3 Multi-Colour and High-Speed Printing

Multi-colour pad printing machines are becoming popular due to:

- Faster production of colourful designs

- Ability to print complex logos and patterns

- Reducing setup time for multiple prints

Brands benefit by producing eye-catching products that stand out in the market.

2.4 Eco-Friendly Inks and Improved Ink Systems

Environmental regulations and sustainability concerns are driving the adoption of:

- Low-VOC inks

- Water-based inks

- Advanced ink delivery systems

These improvements reduce environmental impact while maintaining high-quality prints.

Conclusion

Pad printing machines are a reliable, versatile, and cost-efficient solution for modern manufacturing needs. With their ability to print on complex shapes, use multi-colour inks, and integrate with automation, they are essential for electronics, automotive, FMCG, cosmetics, and promotional merchandise industries.

Ready to boost your production and branding capabilities? Contact Meditek Printing Solutions today to explore high-quality, automated pad printing machines for your business and maximize your profitability in 2026!